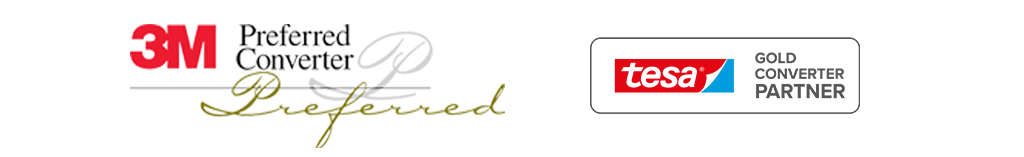

DIE-CUTTING

We can cut in half or cut through any shape requested by the customer.

The die-cutting can be carried out on rolls, for manual or automatic applications, or on multi-yield or single sheets: both versions can also allow for the easy removal of the liner.

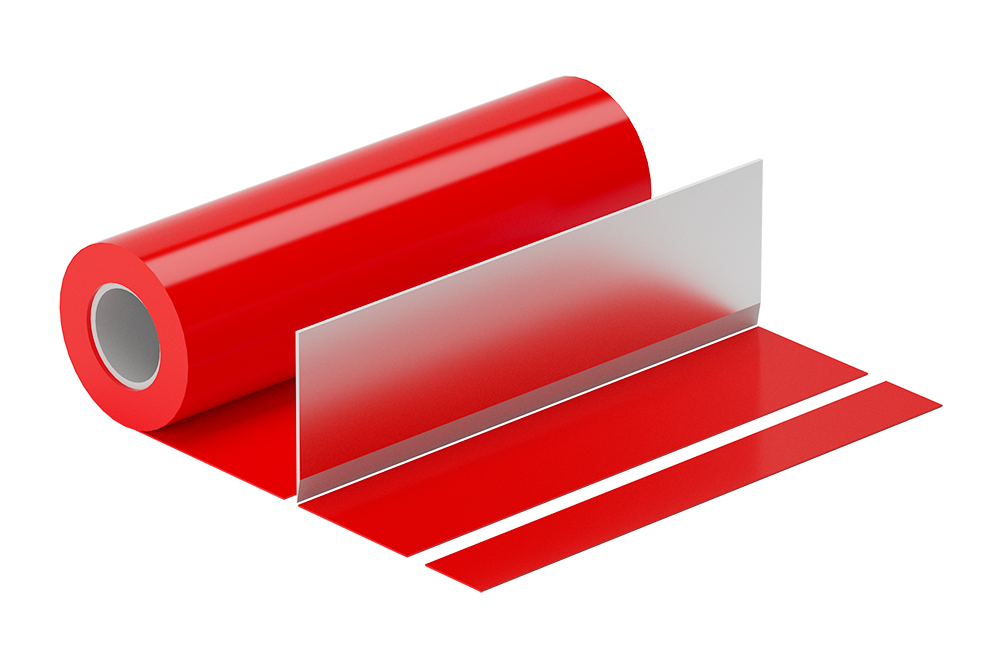

CUSTOMISED ROLL CUTTING

Cutting of rolls of double-sided adhesive, single-sided adhesives and expanded foam of a minimum of 3 mm

in width.

LASER & WATERJET CUTTING

High-speed laser cutting and productivity for highly accurate processing with cutting accuracy of + 0 / – 0.1 mm

Through-cuts, half-cuts and engravings can be carried out on many types of materials, allowing any shape to be produced without the need for implants.

SHEETING

The creation of customised sheets upon the customer’s request, starting from rolls or from larger sheets.

COUPLING

Coupling, even when hot, of mono- and double-sided adhesive on various materials on reels or sheets.

REWINDING

Thanks to our precision machinery, we are able to supply rolls or reels in various sizes, always guaranteeing a high-quality product.

Third-party processing

Coupling and packaging of double-sided adhesives made by us on customer’s products, following custom packaging specifications.

Work island in protected area for using primers and cleaners before the laminating stage.

Are you interested in our processes?

To receive a free consultation, an inspection or a personalised quote,

fill in the form below with the required data and you will be contacted by our experts.